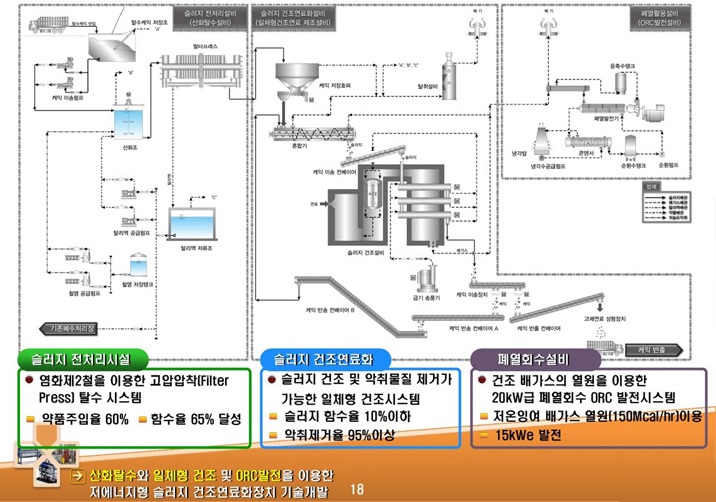

Development of Low-Energy Sludge Drying and Fuel Conversion Technology Using Integrated Oxidative Dehydration, Drying, and ORC Power Generation (2015)

Low-Energy Sludge Dehydration and Drying Integrated Treatment Technology (2007)

Characteristic

- Integrating the dehydrator and dryer into one filter press (no separate dryer is required except for attached facilities)

- Drying method that realizes high-efficiency energy using hot water and vacuum (use water of 90℃ or less)

- Selectable “Draining” or “Draining + Drying” mode (operation mode can be selected during operation)

- High pressure dehydration (15kg/cm2 compression pressure) and fully automated continuous operation function

- Control of moisture content of sludge cake is possible (adjustment of moisture content through control of drying time)

- Reduced process time

Usage

- Solid-liquid separation process for the production of drinking water, sewage, various industrial wastewater, and raw materials

Composition of dehydration and drying complex treatment technology

- MMI & Control Panel

- Dehydration and Combination Filter Press Body

- Drying and other Auxiliary Facilities