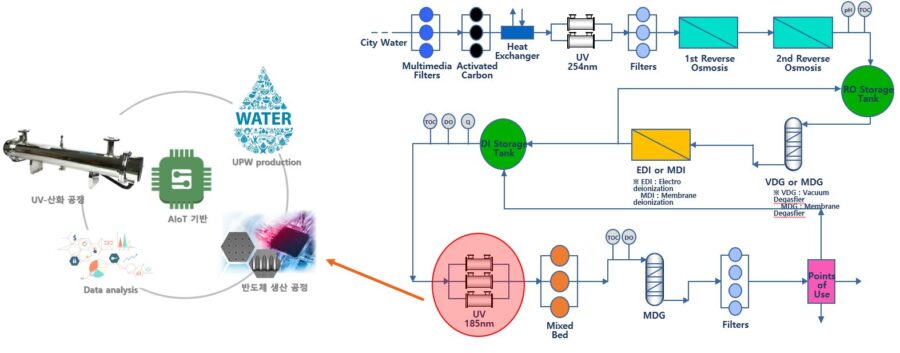

Development of AIoT (Artificial Intelligence of Things) Based UV Oxidation System for High-Purity Industrial Water Production (ASTM D5127 E-1.3 Grade)

Goal

Development and Demonstration of AIoT (Artificial Intelligence of Things) Based UV Oxidation System for High-Purity Industrial Water Production (ASTM D5127 E-1.3 Grade)

Research Content

1. Development of improved UV lamp performance for oxidation to enhance irradiation intensity and lifespan

2. Development of CFD modeling-based UV reactor for oxidation (1,500 ton/d scale) for high efficiency and minimized installation area

3. Development of AIoT-based self-diagnostic control system

4. Performance evaluation and derivation of optimal operating conditions through long-term operation of full-scale facility

5. Development of TOC removal and oxidant generation prediction simulator system

6. Development of UV fluence optimal dosage control logic according to water quality changes

Development of UV Lamps for Oxidation to Improve Irradiation Intensity and Lifespan

- Development of lamp emission paste

- Development of optimal mixing ratio of inert gas

- Coating technology for suppressing oxide deposition

- Performance comparison evaluation between imported vs developed lamps

- Output degradation test according to lifespan

┃ Collaborative Research Evaluation ┃

Development of CFD Modeling-Based UV Reactor for Oxidation for High Efficiency

- UV reactor lamp arrangement and baffle optimization design based on CFD analysis and approximate optimization modeling

- Development of corrosion-resistant lamp connectors and fatigue fracture prevention type sockets for quartz tubes

- Design of UV oxidation systems by treatment capacity for certification testing

┃ International Certification Acquisition ┃

Development of TOC Removal & Oxidant Generation Prediction Simulator

- Development of 185~300nm UV Fluence analysis module

- Development of oxidant (DO) generation and TOC removal rate analysis module

- Development of UV reactor conceptual design module

- Simulator SW packaging

┃ Collaborative Research ┃

Development of Machine Learning-Based Self-Diagnostic UV Reactor Control System

- Construction of data machine learning system

- Construction of optimal control decision support artificial intelligence (AI) system

- Modular oxidation reactor integrated control function

- Flow rate and water quality change-linked linear lamp output control function

- Development of oxidant generation suppression function due to excessive UV irradiation

- Development of output compensation control function when lamp fails (less than 10%)

┃ General + Collaborative Research ┃