Advantage

Application

Advantage

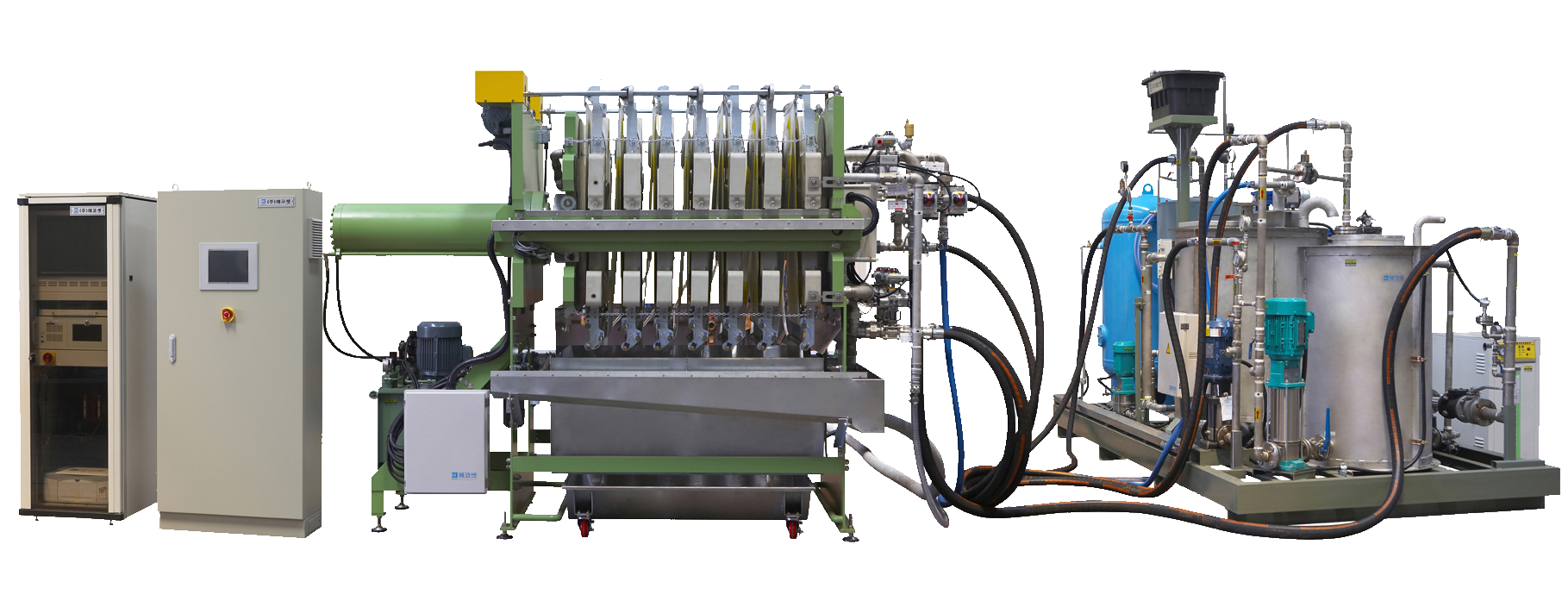

- Unique dehydration technology differentiated from traditional filter press

- Short cycle time of 60min or less (potable water sludge)

- Double moving head filter plate to minimize footprint and increase output

- Complete removal of the sludge cake by moving the filter cloth upside down

- Highly efficient filter cloth cleaning on inside and outside increase lifespan

- Low moisture content of cake leading to cost saving

- Complete cake discharge and cleaning process and complete automation

Application

- Portable Water and industrial sludge processing

- Municipal sewage and industrial wastewater

- Chemical plant manufacturing process

- Food Industry

- Ceramic and mining Industry

- Metal Industry

- Dye and pigment Industry

- Fermentation Industry

- Petrochemical Plant